Packaging design and manufacturing service provider

Views: 2 Author: Site Editor Publish Time: 2022-06-29 Origin: Site

Cosmetic products on the market use a variety of packaging process. In fact, in terms of cosmetic packaging, not only for the pursuit of beautiful and good looking , good packaging can increase the value of products.

BEYAQI COSMETICS(HANGZHOU) CO.,LTD as a professional manufacturer of more than 13 years of experience in the field of empty lip gloss tube, customized lipstick tube packaging, private label cosmetic packaging etc. Today we will list some commonly used process for you, I hope this article can give you a reference.

It is definitely a process that must be mentioned. A lot of positioning in cosmetic packaging of high-end brands, often used in this process. UV generally refers to the printing effect process, is in a print on the pattern you want above a layer of gloss oil (light color, matte color, glitter powder, etc.), mainly in order to increase the product brightness and artistic effect, this can make the whole packaging with a unique texture.It also can protect the surface of the product, high hardness, corrosion resistance and friction, not easy to scratch. The silver eyeshadow plate and silver powder compact in the following picture are using UV printing.

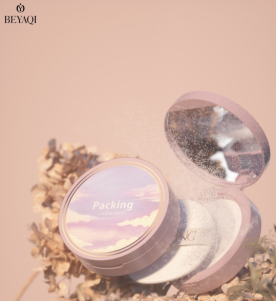

The appearance packaging is mainly offset printing, screen printing and gravure printing, and the printing color is mainly spot color, so as to have a good grasp of the color unity of packaging. If you want to make the packaging color printing more distinctive, it is suggested to combine several printing processes effectively to achieve the special requirements of packaging. The cute powder compact box below is printed using different printing processes.

Hot stamping is a very popular packaging process, which has been used in packaging design more several decades. Cosmetic packaging for hot stamping technology has always had high requirements, not only with high performance equipment, gold paper also has a certain standard. After hot stamping, the pattern is clear, beautiful, bright colors, can make the finishing point, highlight the role of the design theme, often used in cosmetic boxes. The metallic luster of the white lipstick tube in the picture below is the use of hot stamping process.

Electroplating is one of the processes commonly used in cosmetic packaging, which not only increases the appearance, compensates for the shortcomings of plastic, gives the properties of metal, improves its performance in electricity, heat and corrosion resistance. The commonly used electroplating colors of our cosmetic packaging products are mainly shiny gold, matte gold, shiny silver and matte silver, while other electroplating colors and colors biased toward white have relatively poor stability.

Compared with other processes, the delivery time of electroplating process is longer and the processing cost is also higher. If you have enough time and higher requirements for product packaging customers can choose. The pink lip gloss tube and pink air cushion box in the picture below are using electroplating process.

The above process is more commonly used for cosmetic packaging. But if you want to be different, special, innovative , we have other different process for you to choose, such as embossing, 3D printing, relief technology and so on.

If you want to know more, you can bookmark our article or website, private message us for detailed discussion. Thank you.