Graphic original, screen printing, scraping scraper, ink, printing machinery and substrates are the six elements that constitute screen printing, their common role constitutes a wide range of applications, bright colors and strong three-dimensional, good light resistance and can be printed on a large area of screen printing technology. It is common in cosmetic packages, such as in cosmetic jar, lotion bottles.

Read More

As an emerging "beautiful economy" in the cosmetics industry, its development is rapid. It always uses the existing conditions to make its own role as soon as possible, and even without any time and opportunity for people to enter thousands of families. It always uses new technologies, new materials, new images and new concepts to develop itself in a timely manner. It uses a variety of different materials to change the colorful shape.

Read More

Economic development promotes the improvement of people's living standards, which in turn promotes the development of new economic fields.

Read More

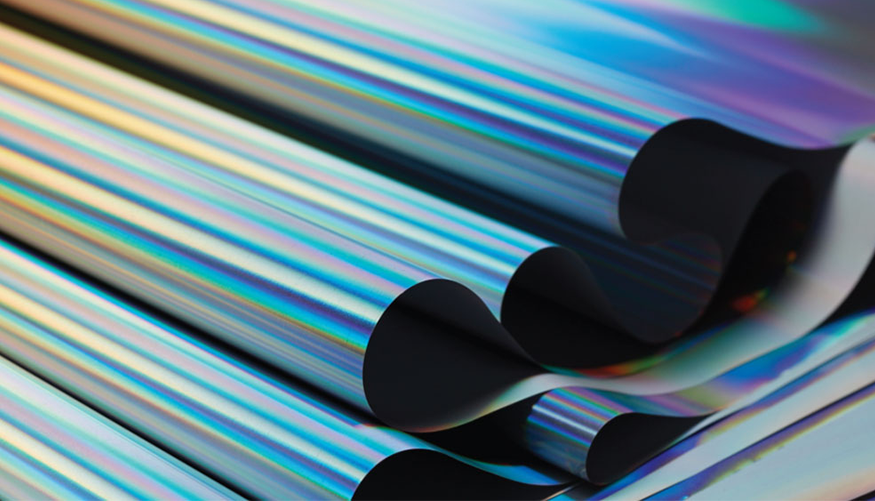

With the rapid development of cold stamping technology, it has come to occupy an important place in aluminium printing. This unique and beautiful printing effect is popular with merchants and customers alike as part of the packaging of goods.

Read More

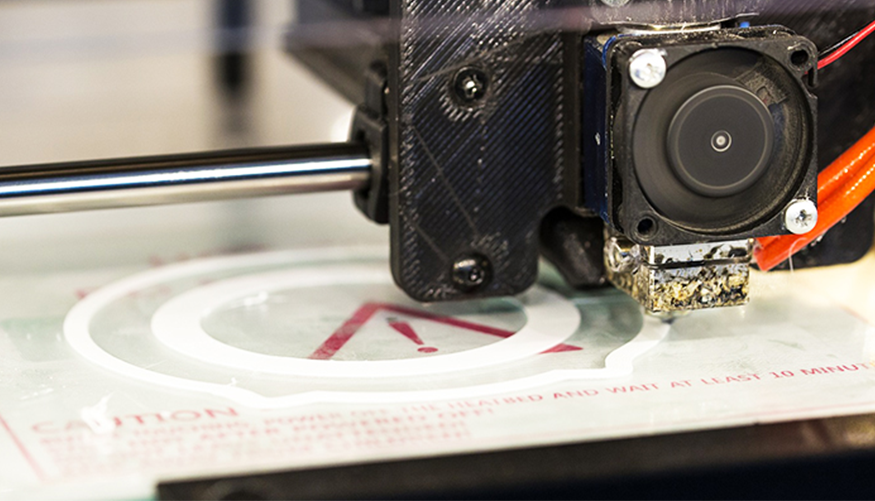

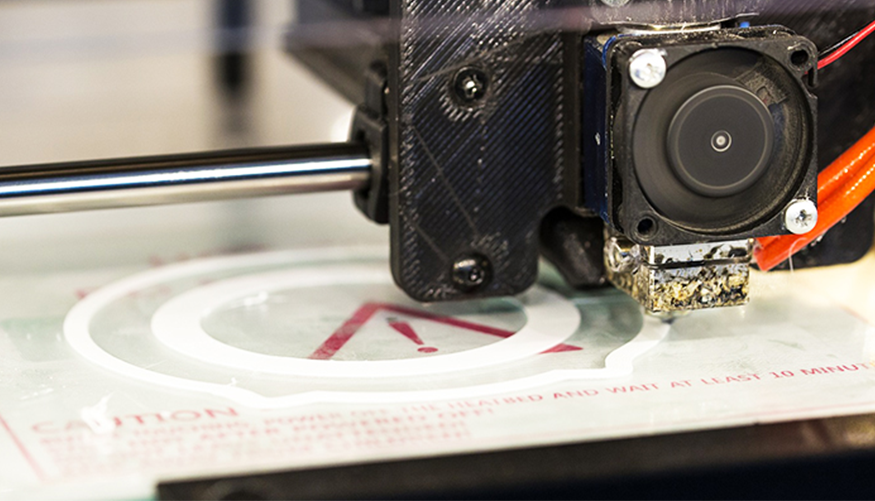

Printing has evolved over the years since it was first documented in China about 1800 years ago. Have we reached the pinnacle of printing with the latest printing method introduced in 1991 in the form of "digital printing"? As assert about new printing processes, let's take a look at the most common printing processes that have shaped the industry as we know it.

Read More

The main factors affecting the quality of hot stamping perfect hot stamping effect mainly depend on the level of temperature, pressure and hot stamping speed with each other. Therefore, to control the quality of hot stamping, should master the reasonable hot stamping temperature, hot stamping pressure and hot stamping speed.

Read More

We have said before, hot stamping is the use of hot pressure transfer principle, the aluminum layer transfer to the surface of the substrate. That is, at a certain temperature and pressure, the aluminum layer will be peeled off from the base layer, and the aluminum layer will be stuck to the hot stamping material.

Read More

Cosmetic packaging mainly includes plastic bottles, glass bottles, tubes, airless bottles, etc., which more or less involve hot stamping.

Read More

In this era when the color cosmetics market is getting bigger and bigger, all kinds of novel brands are emerging one after another, so as a color cosmetics brand, how to let consumers choose you among the products, I think packaging plays a decisive role. It determines whether you will be noticed by consumers in a second.

Read More

1. The definition of hot stampingHot stamping as a special printing technology without ink, environmental protection, clean, and suitable for plastic, glass, paper and other materials;Hot stamping process is to use the principle of heat pressing transfer, to transfers the aluminum layer in the hot s

Read More